Ideas

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Ideas

Events · 19 April 2024

Queers In Property presents 116 Rokeby

Design · 16 April 2024

An extension of the home

Insights · 12 April 2024

Designing for all

Press · 6 April 2024

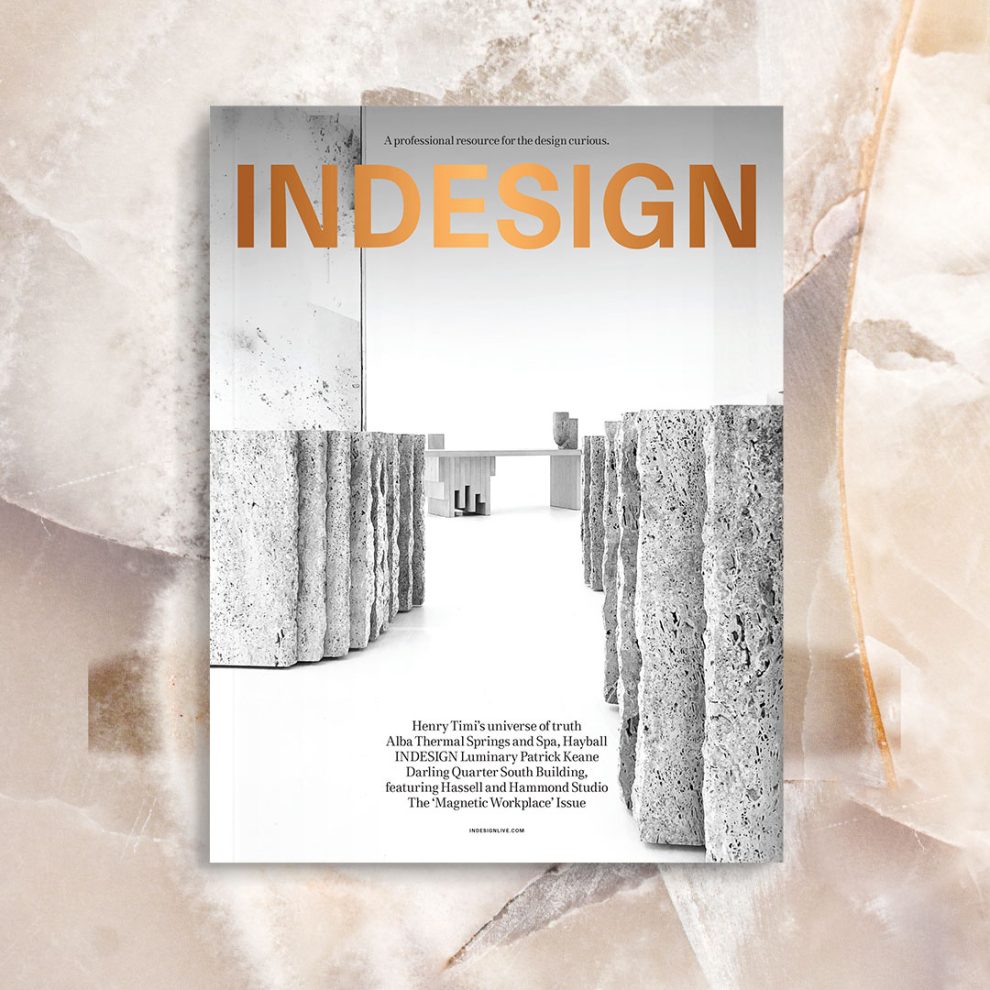

Salta featured on Indesign Live

Awards · 5 April 2024

2024 AIDA shortlist revealed

Design · 22 March 2024

A lesson in refinement

Design · 21 March 2024

In conversation with Helen Kontouris

Insights · 20 March 2024

Richard Beel on why density is an opportunity

Profile · 7 March 2024

Fives minutes with Maree Paraskevopoulos

Insights · 6 March 2024

Watch: A hidden coastal home with breathtaking views with The Local Project

Profile · 4 March 2024

Five minutes with Viya Zhang

Profile · 1 March 2024

Meet RMIT Sue Carr Award winner Rouyi ShaoTian

Profile · 20 February 2024

Five minutes with Sharon Sclarr

Insights · 31 January 2024

Reaching aspirations

Ideas · 24 January 2024

Workplace design: Looking back to see ahead

Press · 9 January 2024

Australian Design Review chats with Stephen McGarry

Design · 29 December 2023

What to expect: a snapshot of projects due for completion in 2024

Ideas · 19 December 2023

Time for rest and play

Ideas · 7 December 2023

A designer’s dream itinerary

Insights · 29 November 2023

BTR: Rethinking a housing need

Awards · 28 November 2023

RMIT Sue Carr Award winner unveiled

Awards · 24 November 2023

835 High Street wins at the 2023 Interior Design Excellence Awards (IDEA)

Press · 13 November 2023

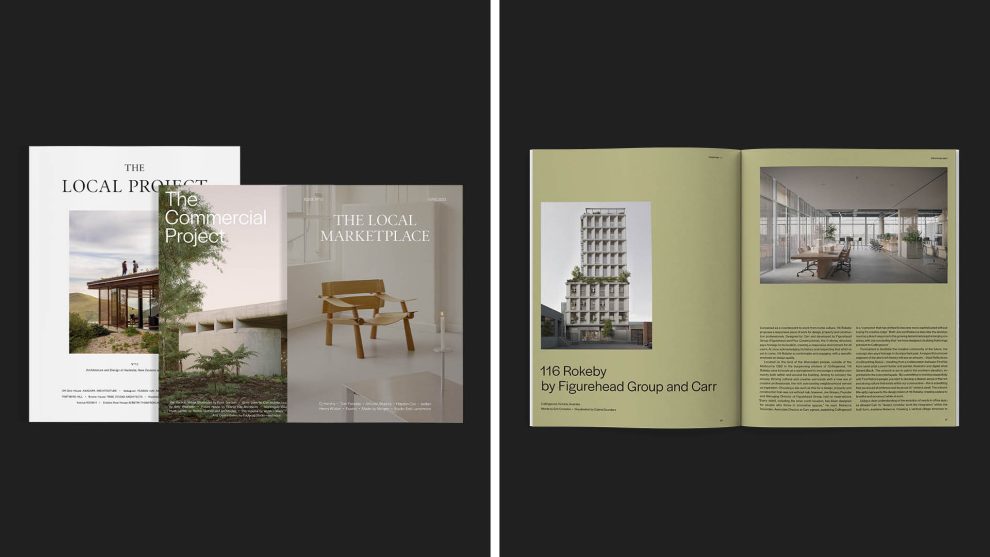

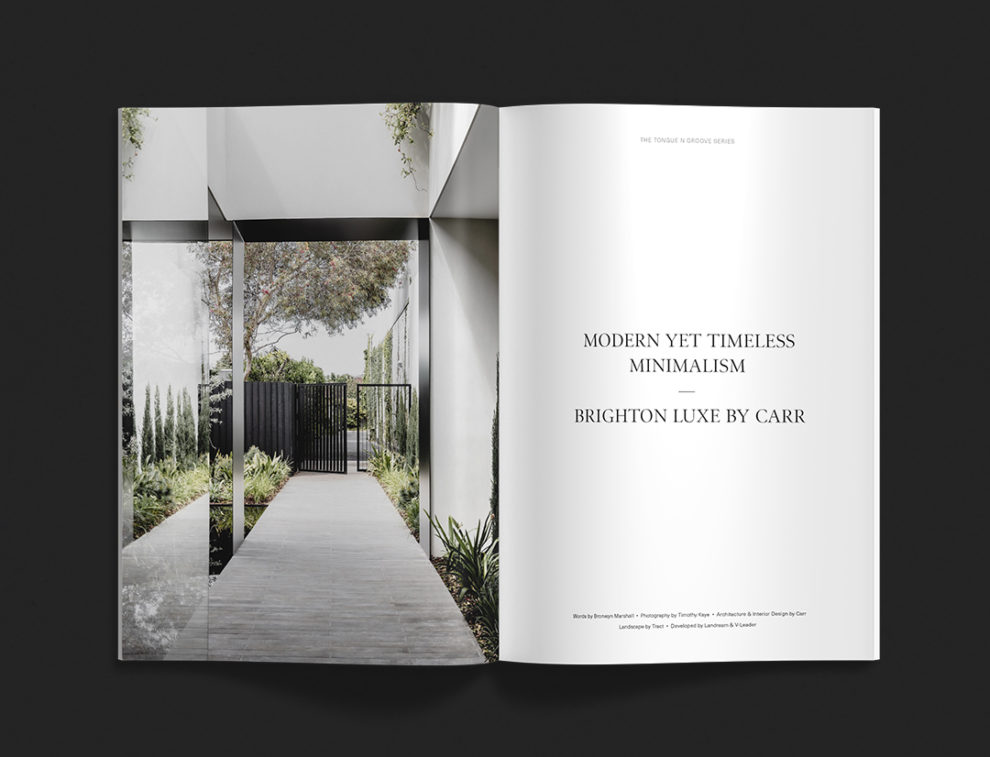

The Local Project releases 13th edition

Profile · 10 November 2023

Five minutes with Marissa Kefalianos

Press · 2 November 2023

Domain explores Como Terraces

Insights · 25 October 2023

The honesty of modelmaking

Awards · 24 October 2023

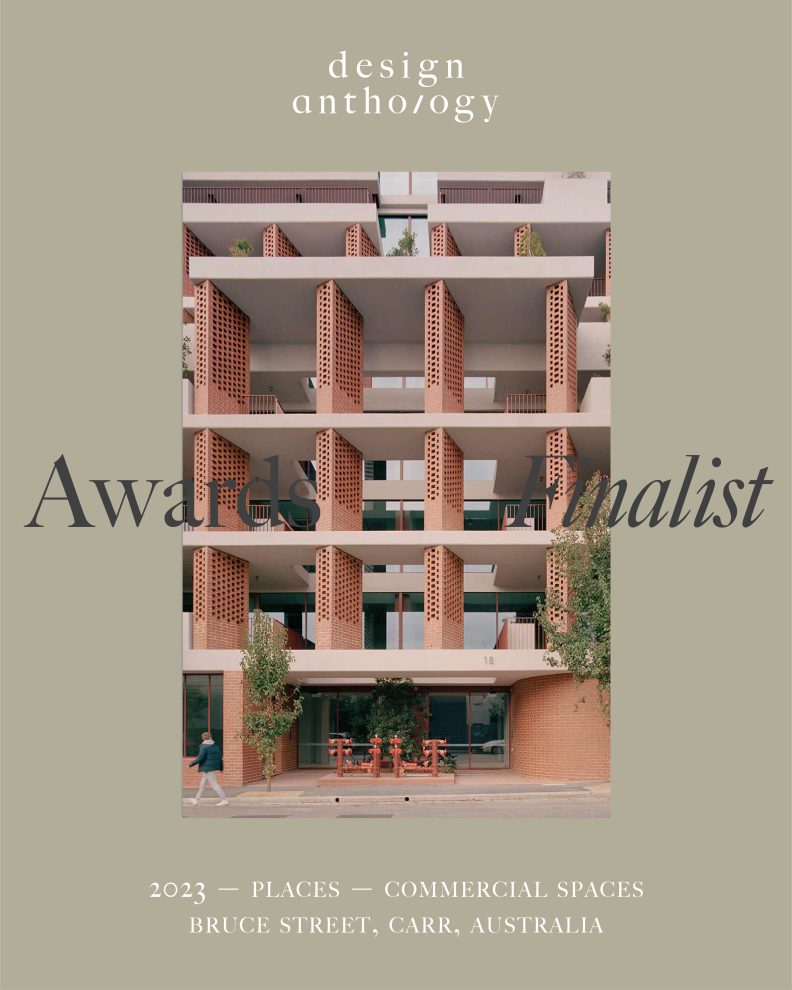

Bruce Street wins Commercial Spaces prize at Design Anthology Awards

Awards · 16 October 2023

Como Terraces wins at PropertyGuru Asia Property Awards

Awards · 16 October 2023

Bruce Street a finalist in Design Anthology Awards

Design · 6 October 2023

Putting in the brickwork

Events · 28 September 2023

The launch of The Brookville, Toorak

Insights · 25 September 2023

Revitalising an asset with Catherine Keys

Awards · 22 September 2023

Victoria & Burke wins Gaggenau Kitchen of the Year award

Insights · 13 September 2023

The visionary pursuit of Como Terraces

Press · 11 September 2023

Dezeen takes a look at Bruce Street

Insights · 8 September 2023

Hotel design: What’s on the horizon?

Profile · 5 September 2023

A day in the life of a Project Architect

Insights · 28 August 2023

The considered workplace

Awards · 18 August 2023

2023 IDEA shortlist

Profile · 10 August 2023

Five minutes with Kirby Humphries

Awards · 31 July 2023

The Gaggenau Kitchen of the Year 2023 shortlist

Insights · 25 July 2023

Exploring architecture in the age of artificial intelligence

Press · 19 July 2023

The Local Project unveils its 12th edition

Ideas · 10 July 2023

Putting the ‘well’ in wellness hospitality at Clerkenwell Design Week

Profile · 27 June 2023

Five minutes with Bianca Dignan

Awards · 23 June 2023

Refinery House wins at the Queensland Architecture Awards

Press · 20 June 2023

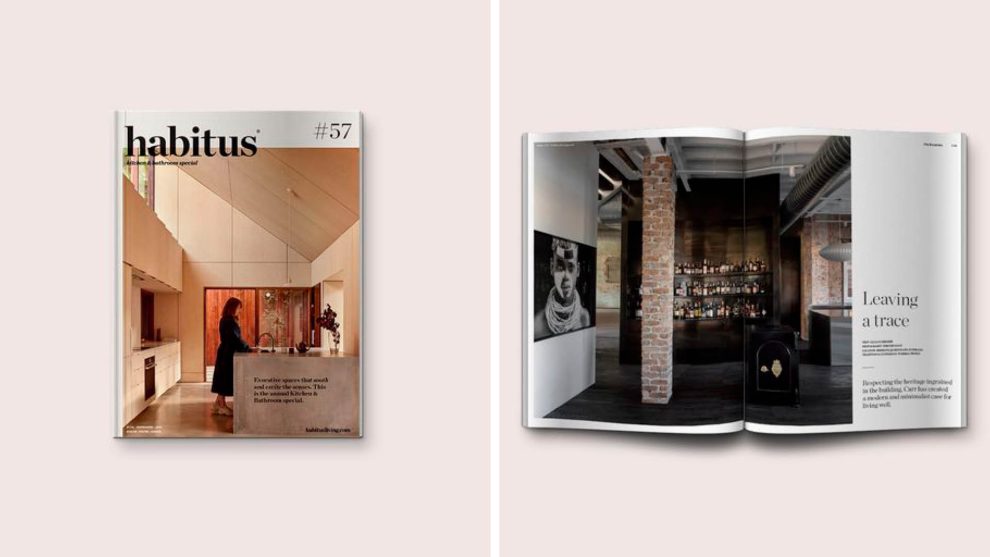

Refinery House featured in Habitus

Awards · 15 June 2023

INDE.Awards shortlist revealed

Ideas · 1 June 2023

116 Rokeby – a case for passive design

Press · 31 May 2023

623 Collins Street makes its debut in Australian Financial Review

Insights · 25 May 2023

When a location is too good to move

Awards · 22 May 2023

Refinery House shortlisted in the AIA Queensland chapter

Insights · 19 May 2023

The balance between functionality and artistry

Press · 10 May 2023

Designing for sensory inclusivity

Press · 8 May 2023

Dezeen explores 835 High Street

Awards · 2 May 2023

Carr shortlisted for AIA award in Victorian chapter

Design · 24 April 2023

116 Rokeby – a new era of workplace design

Awards · 12 April 2023

2023 AIDA shortlist revealed

Design · 3 April 2023

Q&A with Landscape Designer Andy Murray

Ideas · 20 March 2023

The shaping of legacy

Events · 20 March 2023

Salta Properties’ Emma Woodhouse on conscious decision making

Press · 1 March 2023

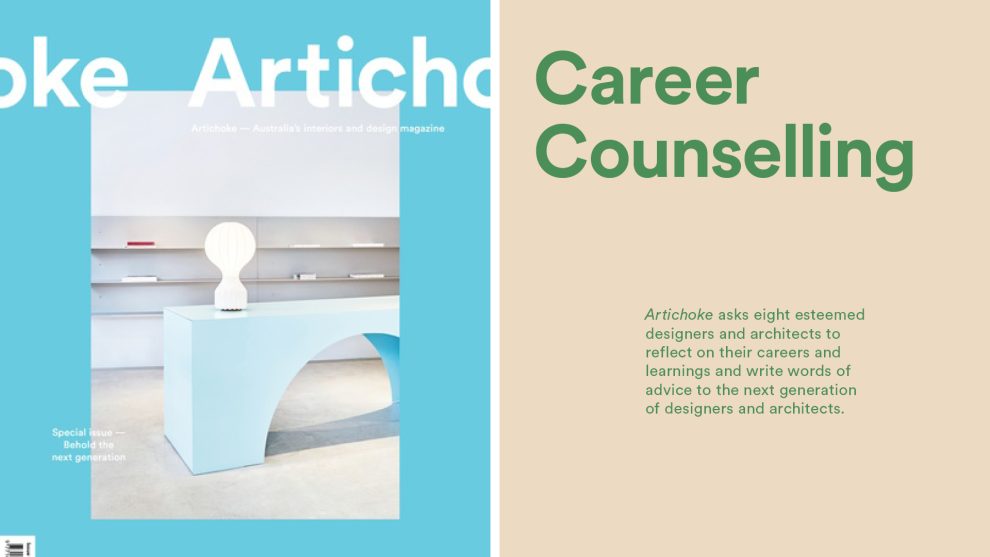

Sue Carr’s advice for the next generation

Press · 23 February 2023

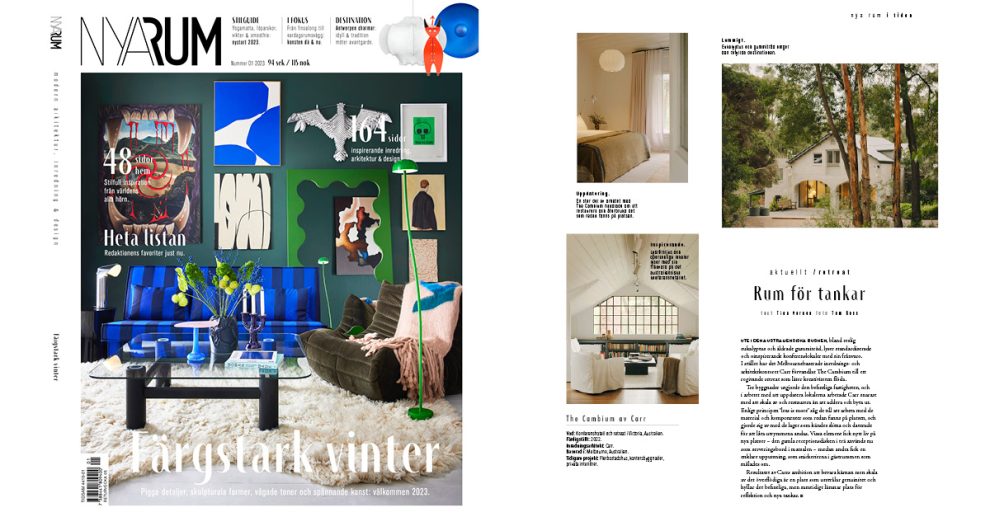

Nya Rum features The Cambium

Press · 20 February 2023

Podcast interview: stepping up apartment living

Insights · 9 February 2023

Richard Beel and designing for lifestyle

Insights · 1 February 2023

Achieving excellence at scale

Profile · 17 January 2023

Q&A with RMIT Sue Carr Award recipient

Design · 9 January 2023

Welcoming 2023: a snapshot of projects due for completion

Press · 19 December 2022

Australian Design Review talks with Bianca Dignan

Ideas · 12 December 2022

Unwinding over summer

Profile · 9 December 2022

Crafting the perfect place for retreat

Awards · 3 December 2022

RMIT Sue Carr Award winner announced

Art · 1 December 2022

Finding proportion and scale – a photo essay by Architect Chris Eggleston

Awards · 29 November 2022

Heyington wins at the 2022 Interior Design Excellence Awards (IDEA)

Design · 7 November 2022

Designing architecture and interiors as one

Press · 3 November 2022

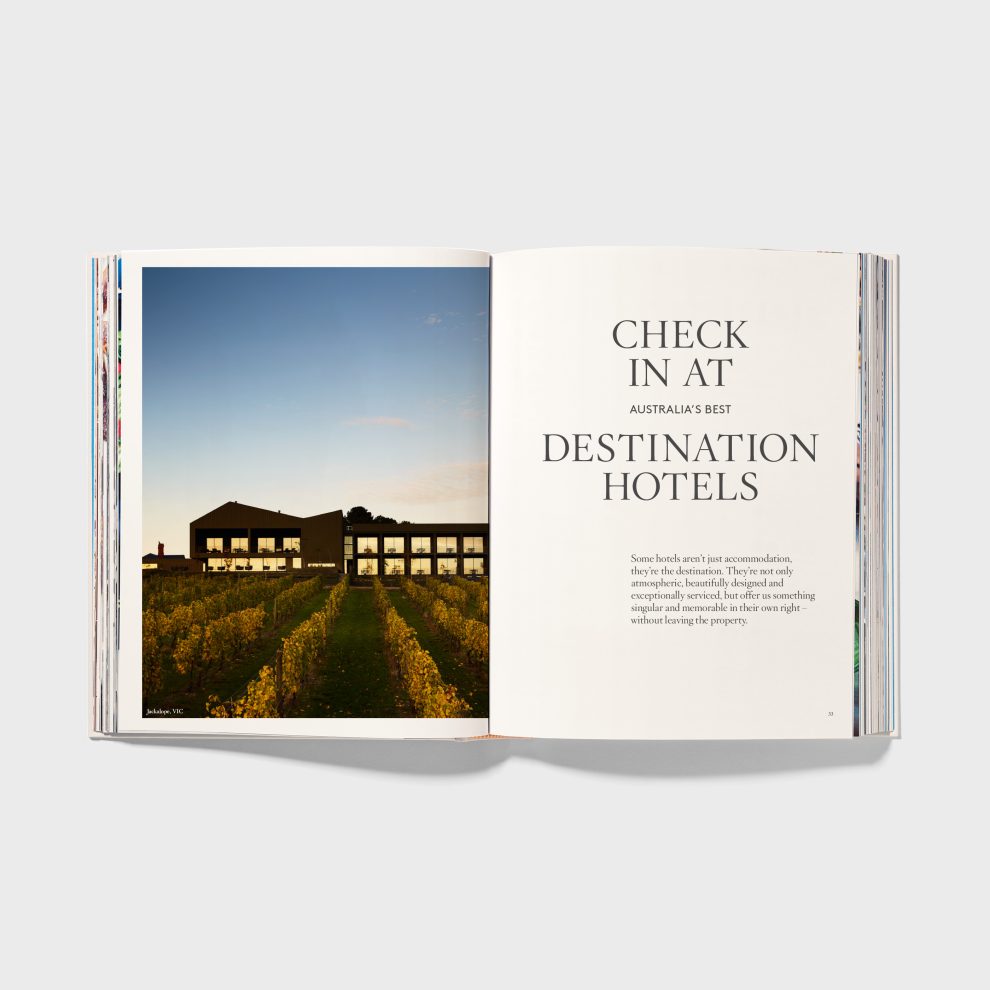

Travels – Broadsheet’s latest book

Press · 14 October 2022

The Cambium featured on Design Anthology

Press · 14 October 2022

The Local Project releases its 10th edition

Profile · 10 October 2022

Introducing Associate Director Candice Bradley

Design · 7 October 2022

Reviving Sorrento Sailing Couta Boat Club

Press · 4 October 2022

The Cambium featured on Indesign Live

Press · 21 September 2022

Habitus Living feature Heyington

Design · 12 September 2022

The design thinking behind Victoria & Burke

Press · 9 September 2022

Broadsheet explores The Cambium

Insights · 25 August 2022

Rise of city-fringe commercial hubs

Art · 22 August 2022

Q&A with artist Ryan Hoffmann

Awards · 22 August 2022

2022 IDEA Awards shortlist

Awards · 19 August 2022

Olderfleet wins state PCA award

Insights · 8 August 2022

ASMR and adapting how we communicate

Insights · 30 July 2022

The power of brand

Profile · 13 July 2022

International telecommuting: an architect’s experience

Press · 6 July 2022

United Places – Hotels that elevate a spirit of place

Profile · 29 June 2022

Five minutes with Etoile Nasrallah

Profile · 23 May 2022

Nicci Green and her artisanal nature

Awards · 20 May 2022

Double workplace finalists at Property Council Awards

Design · 19 May 2022

Como Terraces Welcome to Country

Awards · 16 May 2022

United Places receives Tripadvisor Award

Insights · 9 May 2022

200 Queen Street revisited

Insights · 6 May 2022

Norton Rose Fulbright revisited

Insights · 4 May 2022

Generational timelessness

Awards · 3 May 2022

2021 Master Builders Association National Awards

Insights · 22 April 2022

Understanding ‘boomerang employees’

Awards · 21 April 2022

Archello names Melbourne’s best 25 architecture firms

Insights · 8 April 2022

An exploration of design philosophy

Design · 6 April 2022

2-10 River Street, South Yarra, forges ahead

Design · 30 March 2022

Boutique residential design essentials

Design · 15 March 2022

NGV Contemporary: once-in-a-generation cultural landmark

Ideas · 8 March 2022

Making work meaningful

Insights · 7 March 2022

ISO certification and the afforded possibilities

Press · 4 March 2022

The Local Project’s newest publication featuring Como Terraces

Profile · 2 March 2022

Five minutes with Lauren Kay

Design · 7 February 2022

Officially ISO certified

Insights · 4 February 2022

Why we use concrete

Insights · 2 February 2022

The Westin revisited

Profile · 25 January 2022

Five minutes with Sam Stefanou

Profile · 11 January 2022

John Bradley’s quest for knowledge

Insights · 6 December 2021

A renewed sense of optimism

Events · 3 December 2021

QHouse x Como Terraces

Ideas · 3 December 2021

Carr holiday reading list

Ideas · 1 December 2021

A summer guide from our friends

Awards · 26 November 2021

Olderfleet wins at the 2021 WAF Awards

Design · 16 November 2021

The International Brighton breaks ground

Insights · 15 November 2021

Jackalope – a sustainable benchmark

Insights · 15 November 2021

A welcome return for working parents

Awards · 11 November 2021

2021 Sustainability Awards

Insights · 9 November 2021

Marquise apartments revisited

Art · 28 October 2021

Q&A with photographer Dianna Snape

Insights · 21 October 2021

Architecture and Interior Design: a dual discipline perspective

Awards · 15 October 2021

Gaggenau Kitchen of the Year award show

Awards · 1 October 2021

2021 IDEA award shortlist

Insights · 28 September 2021

Watch: a sense of calm

Press · 27 September 2021

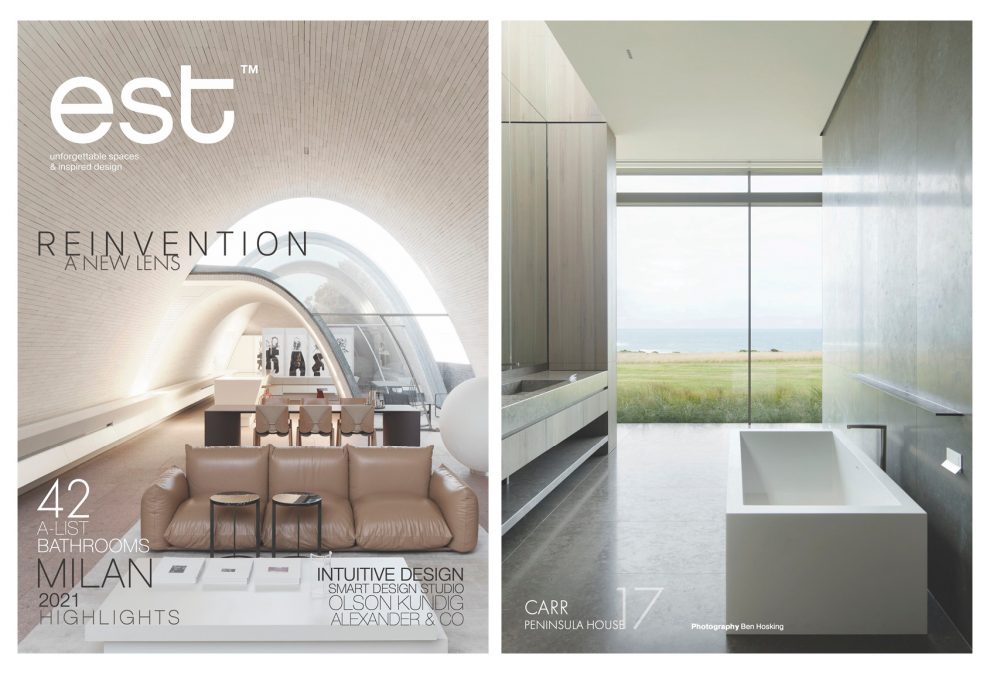

est Magazine’s A-list bathrooms

Design · 23 September 2021

NGV Contemporary competition shortlist

Awards · 17 September 2021

Dezeen Awards 2021 shortlist

Ideas · 9 September 2021

Lessons on remote collaboration

Ideas · 3 September 2021

The Carr podcast list

Design · 2 September 2021

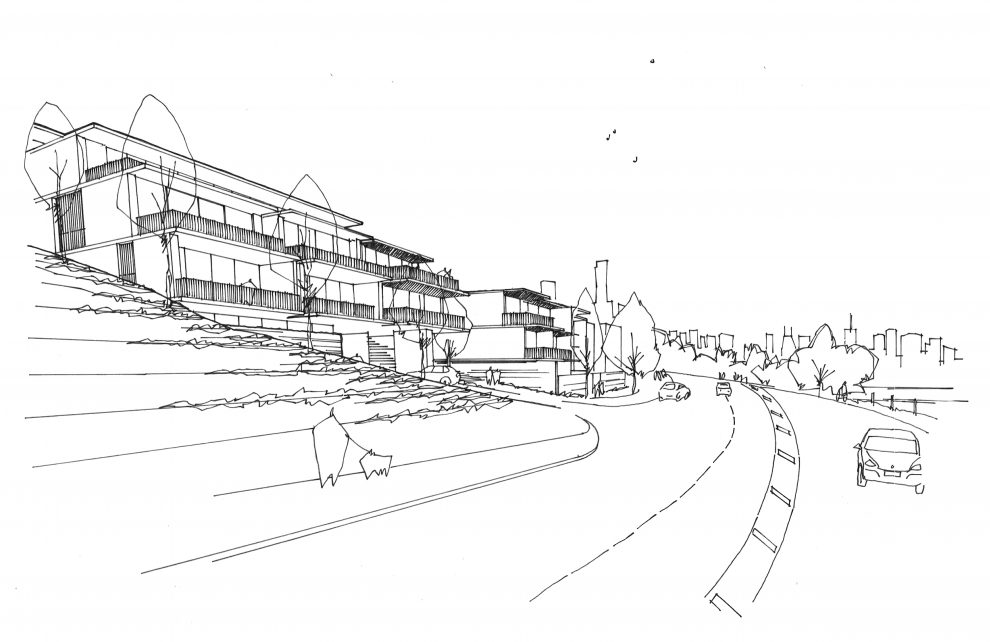

57 Stewart St, Richmond, submits for planning

Insights · 31 August 2021

Merriwee revisited

Ideas · 27 August 2021

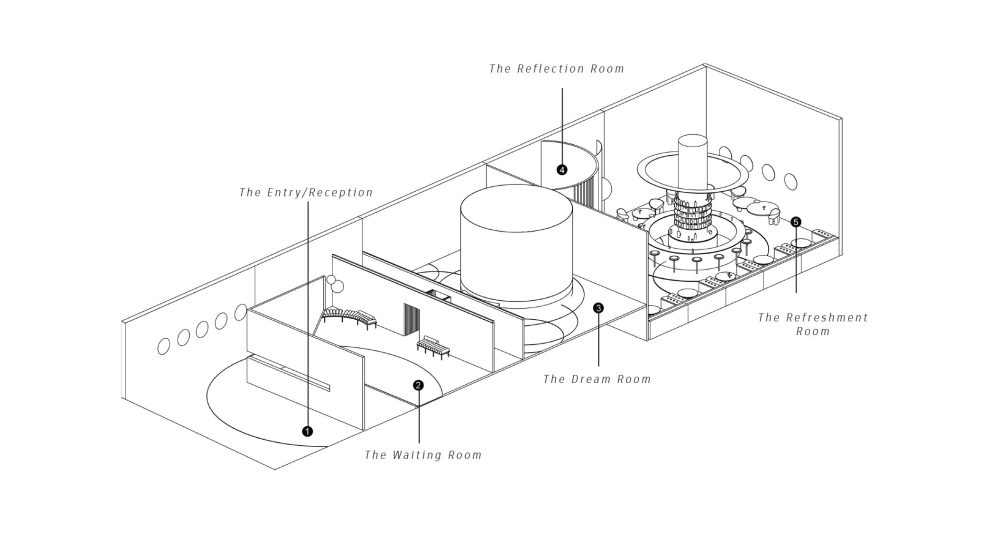

116 Rokeby – a breathing space

Press · 27 August 2021

Space Furniture talks with Sue Carr

Press · 25 August 2021

Talking Design x Sue Carr

Insights · 24 August 2021

Watch: a natural beauty with Habitus TV

Insights · 17 August 2021

Chris McCue reflects on embracing the unknown

Insights · 17 August 2021

Calmly balanced

Design · 10 August 2021

Developing the architectural language for 835 High Street

Press · 23 July 2021

Design trends come and go – Sue Carr’s vision has never wavered

Insights · 16 July 2021

Q&A with Studio Ongarato

Events · 13 July 2021

Open House Melbourne Olderfleet tours

Events · 24 June 2021

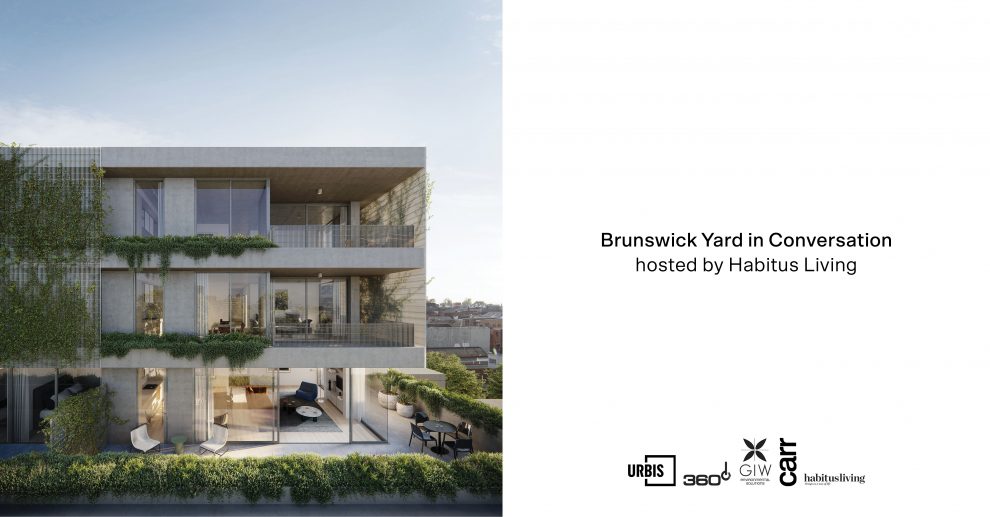

Brunswick Yard in Conversation Webinar

Awards · 19 June 2021

Olderfleet wins prestigious AIA award

Design · 15 June 2021

A life-long pursuit of excellence honoured

Awards · 10 June 2021

Olderfleet shortlisted for INDE.Awards

Insights · 4 June 2021

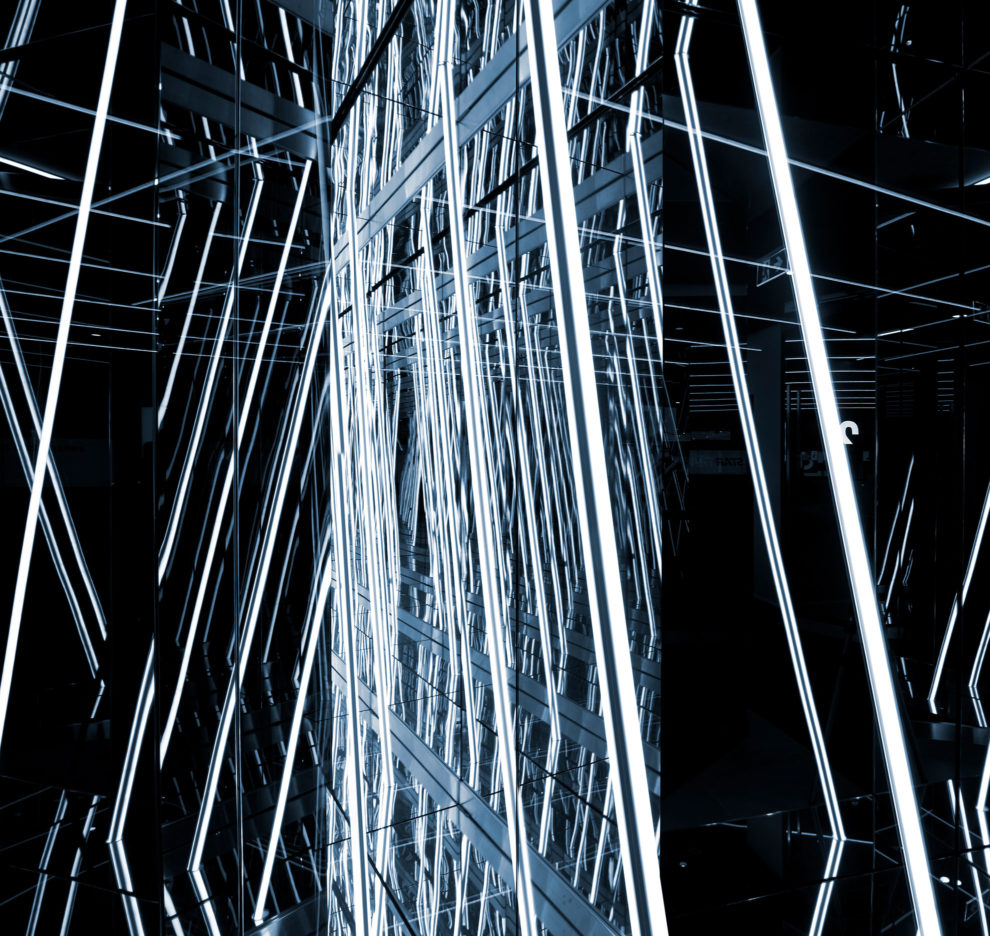

The importance of art in public spaces

Press · 28 May 2021

Como Terraces publicly launches

Press · 27 May 2021

Gaggenau retrospective with Sue Carr

Art · 19 May 2021

Four projects shortlisted for AIDA 2021

Events · 17 May 2021

Carr team celebrates five decades

Insights · 10 May 2021

Five decades in the making: Sue Carr on the evolution of Carr

Insights · 10 May 2021

The curious mind of Robert Owen

Design · 9 May 2021

The story behind ‘Dynamic Restraint’

Events · 6 May 2021

Bentley Drive Day at Jackalope

Insights · 4 May 2021

Collaboration with Articolo Lighting

Insights · 19 April 2021

Law firms for the future

Awards · 19 April 2021

Olderfleet shortlisted for an AIA interior architecture award

Insights · 15 March 2021

A new urbanism

Awards · 22 February 2021

Carr receives a High Commendation at IDEA 2020

Press · 16 February 2021

Chris McCue on New Brutalism, Biophilic design and our new project at Brunswick Yard

Press · 27 January 2021

Norton Rose Fulbright workplaces featured on Kvadrat Maharam

Insights · 14 January 2021

Whitepaper: Changing buyer demands in multi-residential

Press · 10 December 2020

Peninsula House featured in Design Anthology

Design · 8 December 2020

Escaping to the coast

Design · 4 November 2020

Convenience is an understatement: The International

Profile · 26 October 2020

Richard Beel considers the power of materiality in architecture

Design · 15 October 2020

Concrete modern

Ideas · 8 October 2020

The Carr reading list

Awards · 1 October 2020

Four projects shortlisted in the IDEA Awards 2020

Insights · 1 October 2020

In search of lifestyle

Insights · 21 September 2020

Creating value in commercial spaces

Awards · 16 September 2020

97 Mathoura Road a finalist in The Urban Developer Awards

Insights · 9 September 2020

Keeping inspiration high – even remotely

Awards · 7 September 2020

East Melbourne Residence featured in inside magazine and Est Living

Art · 3 September 2020

Q&A with artist Anna-Wili Highfield

Insights · 27 August 2020

Anticipating a rise in regional tourism

Press · 19 August 2020

The importance of place: Monocle releases ‘Only in Australia’ podcast

Ideas · 10 August 2020

What we’re eating and drinking in lockdown

Insights · 30 July 2020

How is the multi-residential market faring?

Profile · 20 July 2020

Nick Carr on navigating a time of constant transition

Art · 9 July 2020

Q&A with Maryanne Moodie

Press · 23 June 2020

The International featured in The Local Project

Profile · 18 June 2020

On bringing value to the workplace with Molly Shelton

Profile · 8 June 2020

David Brooks on enriching architecture with landscape

Awards · 1 June 2020

Carr receives two Commendations at AIDA 2020

Awards · 20 May 2020

INDE.Awards 2020 shortlist – three Carr projects make the cut

Ideas · 19 May 2020

The virtual experience

Profile · 7 May 2020

Sue Carr reflects on business and the value of design

Profile · 1 May 2020

Playing the long game: Stephen McGarry on design longevity

Ideas · 26 April 2020

7 articles to help you navigate the new normal

Insights · 15 April 2020

Shopping in the time of COVID-19

Profile · 1 April 2020

In Profile: Chris McCue

Awards · 31 March 2020

Three projects shortlisted in the 2020 Australian Interior Design Awards

Design · 25 March 2020

Design tips for remote working

Insights · 18 March 2020

Decentralising the workplace

Insights · 17 March 2020

COVID-19 update

Design · 10 March 2020

Celebrating International Women’s Day at Carr

Design · 2 March 2020

The design of everyday rituals

Press · 26 February 2020

Mathoura Road featured on Est Living

Design · 16 February 2020

Into the mind of Christopher Boots

Art · 4 February 2020

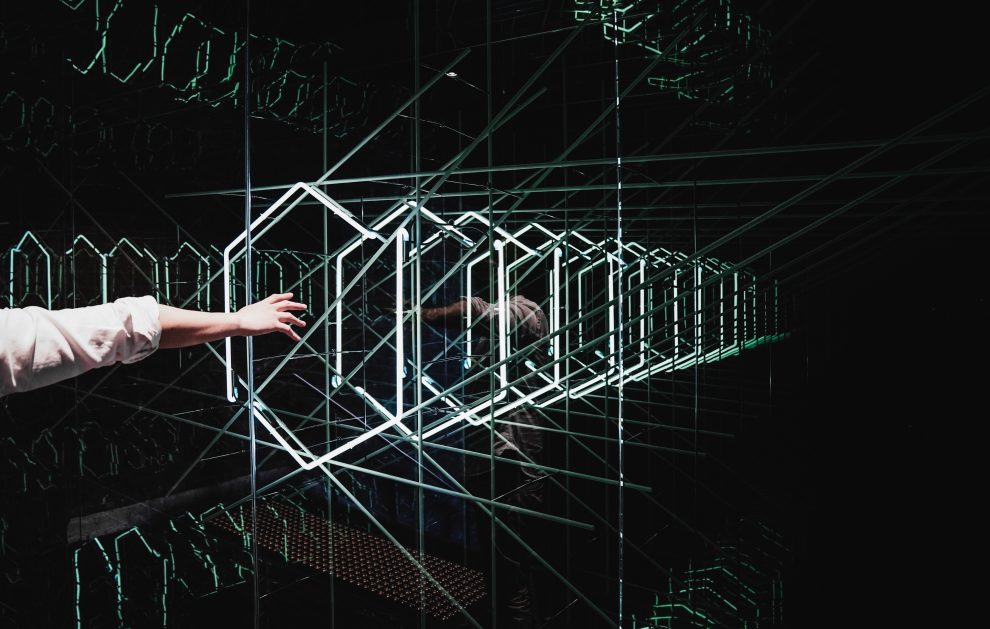

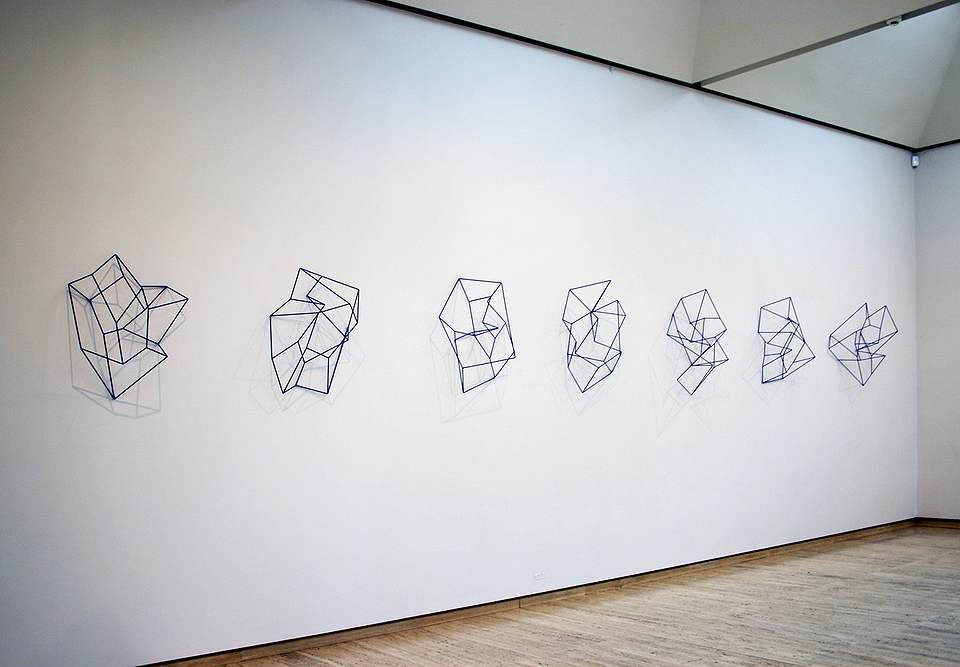

Robert Owen’s geometry of light, space and form

Design · 28 January 2020

Carr launches new website: Step into our design world

Art · 25 January 2020

Head in the clouds

Art · 24 January 2020

Building and nature collide

Insights · 12 January 2020

A new era for legal practices

Art · 10 January 2020

Reframing two icons

Press · 17 December 2019

Crossley Street Hotel in the media

Insights · 10 December 2019

The future of hotel hospitality

Art · 9 December 2019

Japan in a new light

Press · 25 November 2019

Tune in as Carr features on Australia by Design: Interiors

Press · 25 November 2019

Jackalope on Australia by Design: Architecture

Press · 1 September 2019

Eazy Peazy featured on Postcards

Press · 2 July 2019

Vineyard Dreaming – Treasury Wines in inside magazine

Awards · 3 June 2019

Carr wins Hospitality Design Award at the Australian Interior Design Awards

Press · 28 May 2019

131 Residences “Strength & Clarity of Concept” on The Local Project

Press · 9 October 2018

“Red Hill Farm House is a Modern Twist on Vernacular Agricultural Architecture” – Dezeen

Insights · 14 April 2018

On the importance of timeless design

Insights · 7 March 2018

Digital disruption: On the need for focused working

Awards · 22 February 2018

Carr wins World Hotel Interior of the Year for Jackalope

Insights · 6 October 2017

Designing for future generations

Awards · 29 September 2016

Sue Carr named one of Australia’s most influential women

Projects

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Projects

116 Rokeby

A breathing space

Coastal Compound

Contours of the landscape

Salta Properties Head Office

Achieving authenticity

BLVD, Melbourne Square

Shaping a precinct

Albert Street, East Melbourne

Referencing time and place

303 Collins

Rediscovering place and purpose

Malvern Collective

Houses in the sky

Aesop Australian headquarters

Embodying an ethos

Bruce Street, Kensington

Catalyst for rejuvenation

623 Collins Street

A new gateway to the city

Aurora

A home for all on the foreshore

Tank House

A new off-grid experience

MinterEllison Adelaide

Of its place: a homage to Adelaide

Heyington, Toorak

Redefined modern living

Refinery House

Heritage exposed and reflected

Mansard

Carved solidity meets floating forms

Molesworth

Living among gumtrees

The Darley

Grounded on horse racing history

Sorrento Sailing Couta Boat Club

Celebrating craftsmanship

The Cambium

Sanctuary for thinkers, doers and creatives

Richmond boutique office

Inspired by urban fabric

Park Quarter

Dynamic layering

Riverside House

Embedded among landscape

Gridded House

Heritage detailing meets modern generosity

Parramatta Square Public Realm

Providing comfort within a bustling hub

A by Adina

Experiencing Sydney like no other

Alexander Park

Parkside meets bayside

The Berkeley

Timeless sophistication

835 High Street

Defining a new streetscape rhythm

321X

Revived with wellness principles

Pillar+Tide

A play on formal classicism

The Brookville, Toorak

Floating concrete

Como Terraces

Meandering steps to the Yarra River

Olderfleet

A building for a new age

MinterEllison Melbourne

In a class of its own

Eazy Peazy

A layered Japanese aesthetic

Brunswick Yard Display Suite

Breaking with convention

House around a pond

A place of retreat

Lander & Rogers

Creating connection and flexibility at work

Oval Hotel

A sanctuary on a stadium

Brunswick Yard

Concrete contemporary

Norton Rose Fulbright Melbourne

Stepping behind the curtain

Victoria & Burke

Stacking the horizontal, wrapping the vertical

Peninsula House

A pavilion nestled in the landscape

Carter Toorak

Order meets oasis

Norton Rose Fulbright Sydney

Activating the senses

Seafarers

Sculptural luxury defined by the river

Portsea Surf Life Saving Club

Weathering the coast

East Melbourne Residence

A journey of reductionism

Treasury Wine Estates

Elevating hospitality at work

131 Residences

Shifting planes and echoed symmetry

The International, Brighton

Collapsing the threshold between inside and out

Lancemore Crossley St. Hotel

On stage, off stage

Melbourne Square

The essence of Melbourne in design

United Places

Hotel as home: Introducing a bespoke hotel stay

Australia 108

A statement tower

Courtyard House

A play of shadow and light

Blairgowrie Residence

Modulatory meets the coast

215 Spring

Adding a sense of arrival

Gaggenau Melbourne

Activating the senses

Frame House

Framing a secret garden

Red Energy

A quirky office with historic features

Portsea Pavilion

Screening views through timber

Australia Post Star Track House

A great glass atrium

Norton Rose Fulbright Perth

Instilling movement through curves

Westin Hotel

Design classicism

Asciano Sydney

Industrial chic on an epic scale

Aickin Chambers

Redefining what a legal chamber can be

Australia Post Sydney

How to bring branded subtlety into the workplace

Merriwee Residence

An enduring pavilion in the trees

10 River, South Yarra

A glowing box of folded glass

Marquise Apartments

When a sculptor and an apartment tower collaborate

52 Lansell Road

A moody palette for luxury living

Jackalope Hotel

The art of transformation

Hilton Brisbane Conference and Events Centre

Drama and elegance

The Granton

Downsizing in style

South Yarra Residence

Crisp detailing fused with heritage charm

Mosman Residence

Design essentialism

Signorino showroom

Monolithic retail

Red Hill Farm House

Rural narratives brought to life

Riverlee Offices

A workplace with heart and soul

97 Mathoura Road

Six homes for respite and joy

Studio

Studio

What does it mean to elevate everyday experiences?

Carr is an Australian architecture and interior design studio with a timeless approach that fosters connection.

With five decades of design practice, our award-winning expertise in residential, commercial workplace and hospitality, is guided by an innate understanding of space, form, light and materiality.

An integrated perspective ensures every detail is thoughtfully considered, coalescing in work that forges new ground while remaining true to our enduring philosophy and vision.